Getting Comfortable with Safety Factors

Essentially a rescue system starts at the anchor and ends at the load for the mainline and goes from a separate anchor to the load for the belay as well. Together, they function as a system to raise, lower or otherwise move a load from one location to another.

When you build a system there are several things to consider. How much does the load weigh? How far do you need to move it? What type of lowering/raising system are you going to use? What equipment is available? Are anchors readily available or do you need to create one? How strong do you want it? How strong does it need to be?

Presuming—because you all know what happens when you assume—you have a written guideline for safety factors (i.e. rig to a x:1 safety factor whenever possible) and you know the strengths of materials, what suitable anchors are present and the location of the rescue victim, you can start to plug the parts and pieces into the rescue system. Do the strengths of materials really matter? Yes. In order to determine the Static System Safety Factor (SSSF) you need to do some quick field calculations: weight, equipment strength, angles, etc. all come into play.

Determining the static safety factor is much easier than determining the dynamic safety factor because there are fewer variables involved. A static system isn’t moving; therefore, forces are more predictable. Determining how strong the system is when it isn’t moving allows you to ensure it can handle a potential dynamic event.

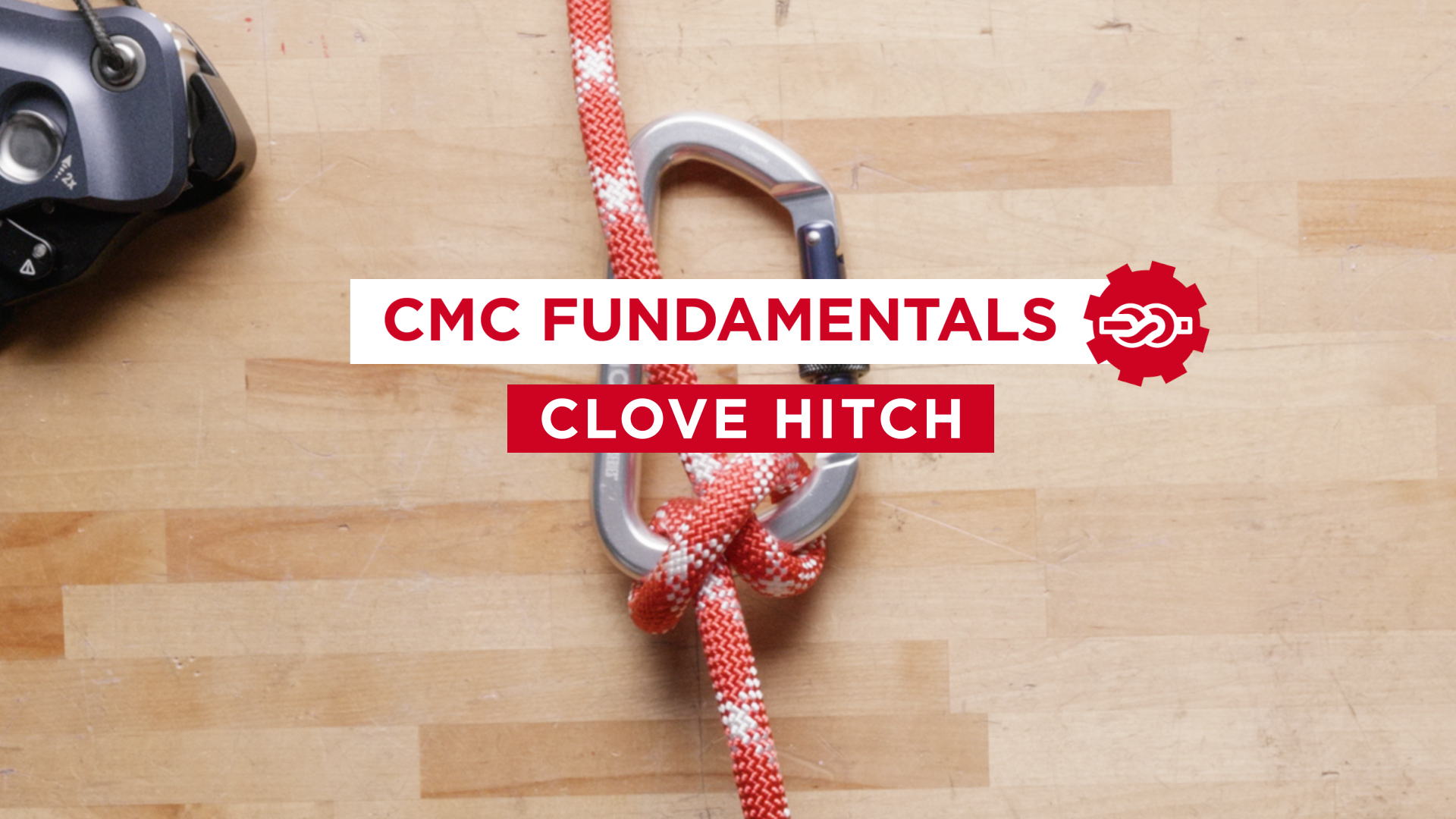

In order to calculate the SSSF you need some information. For illustration purposes, let’s say you have a rope with a 2 kN load run through a high point with a change of direction (COD), creating a 0-degree angle at the top. The rope then runs down through a secondary change of direction at the base and creates a 90-degree angle at the bottom. Since angles make a difference in our force calculation you need to keep them in mind. The rope then runs back to the main anchor point for our raising/lowering system.

Angles also make a difference in force calculations. Since you probably didn’t memorize the entire sine chart, there are three: 0 degrees = 2 X force; 90 degrees = 1.41 X force; and 120 degrees = 1 X force. If you know the strengths of the components you’re using to build the system, you can do some quick calculations and plug in the pieces where they serve the most good. For instance, if you have one 30 kN pulley and one 40 kN pulley, put the stronger one at the top where you have the 0 degree angle. Why? Because the force at the top is doubled so it’s actually 4 kN instead of the original load of 2 kN. Use the 30 kN pulley at the bottom change of direction because the 90 degree angle creates a 1.41 X force, which delivers 2.82 kN at the COD anchor. (Firefighters usually round off so in this case 1.5 kN would equal 3 kN at the COD anchor).

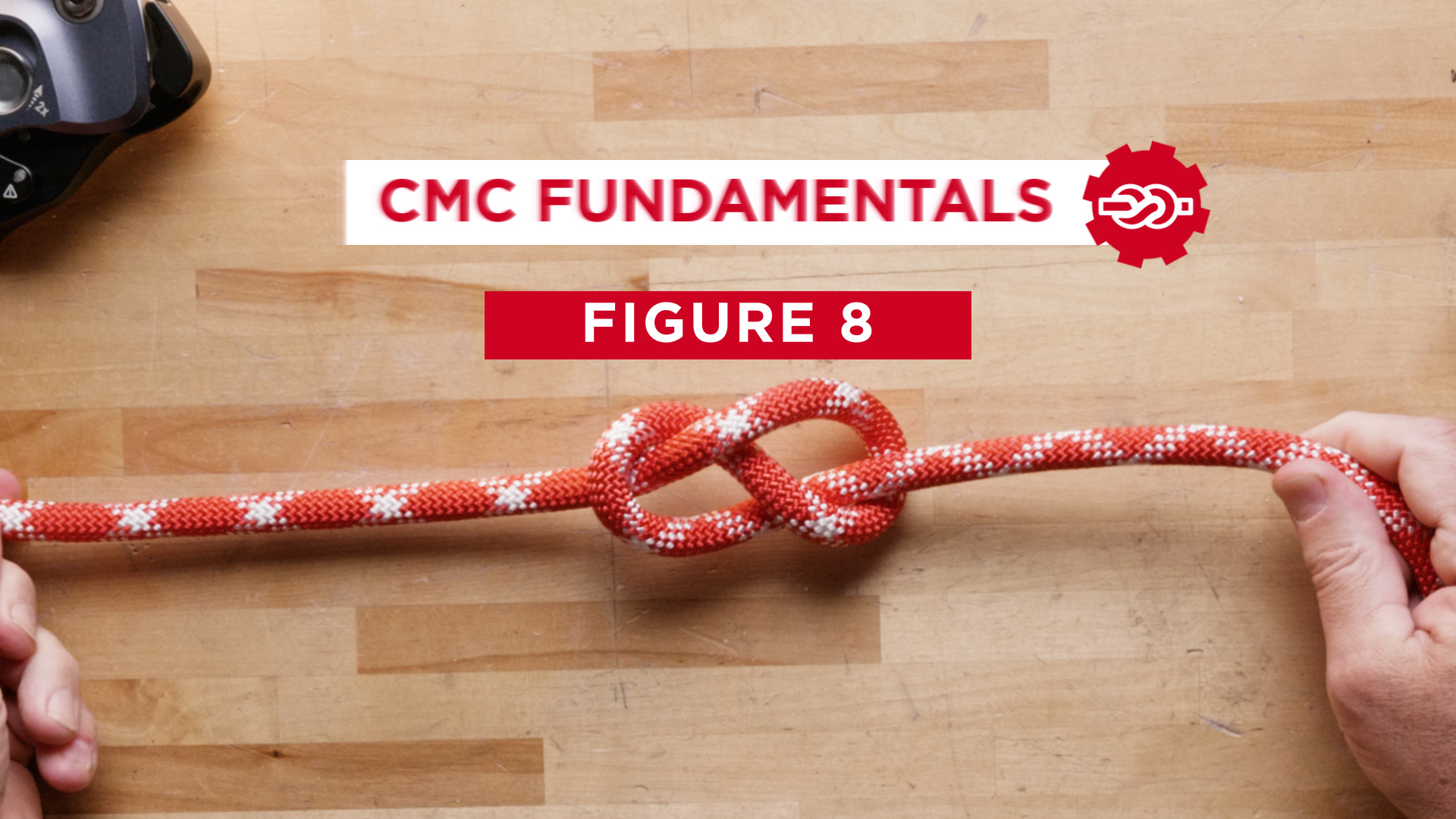

When calculating SSSF, start at the load and work your way to the anchor. If you have 12.5 mm rope with a figure-8 on a bight knot connected to the 2 kN load with a 40 kN carabinerp, the strength of your rope is reduced by about 25% at the knot so it’s now 30 kN at the knot. The rope travels up through the 40 kN, which is attached to the high point with a 40 kN carabiner, down to the 30 kN pulley, which is attached with a 40 kN carabiner to the COD, then back to the main anchor.

In this instance, the weight at the high point is doubled due to the angle so it’s 4 kN. By dividing the pulley strength by the weight of the load you get a quick look at the safety factor at that point. In this case, 40 kN (pulley/carabiner) / 4 kN (weight/force) = 10. So you have a 10:1 safety factor at that point in the system. Continuing down to the secondary COD, do the same thing: 30 kN (pulley) / 3 kN (weight/force) = 10. So you have a 10:1 safety factor at that point in the system. Presuming the main anchor is bombproof—let’s say 54 kN (27:1)—the overall SSSF in this case is 10:1. You want to look at the system overall and determine where the potential weak spots/failure points may be, then plan accordingly for the appropriate parts and pieces to be used where they will do the most good.

Where do you stand as far as an individual? An organization? Where is your comfort zone for safety factors? 2:1? 5:1? 10:1 or something else? Take the time to do the math. Some folks say the higher the better. I look at it this way: There are certain situations where less is more.

LeRoy Harbach

Senior Instructor

CMC Rescue School